Study of Ageing and Production of Wine from Grape fruit by Fermentation process

Guo.X.X1, Wang.J2, M. Gulfraz3, Shi.L4, Tian.J5

1,2,4 College of Food Science and Engineering , Agricultural University of Hebei, Baoding 071001;

3.Visiting Scientist (University of Arid Agricultural Rawalpindi, Pakistan )

5. Biotechnology Research Institute, Chinese Academy of Agricultural Sciences, Beijing 100081)

Abstract:

Fermentation biotechnology is an important industrial process for the production of alcoholic beverages including wine. However, ageing of wine is always an important issue during production. In present study a attempt has made to produce wine by fermentation process along with the assesment of ageing of wine. In this experiment Grape fruit (jufeng) was used as a raw material and fermentation process was carried out with yeast (Saccharomyces cerevisiae) at 28℃. During experiment growth of yeast cell, total solid contents and degree of liquor alcohol was considered critically. The various alcoholic compounds was analyzed with selective method of gas chromatography. Results obtained in the present study indicates that volume of all compounds like ethyl acetate, propyl alcohol, isobutyl alcohol, isoamyl acetate,isoamyl alcohol and ethyl formate was increased with the function of time during fermentation. While during ageing process the contents of methyl acetate, ethyl acetate, isoamyl acetate and ethyl lactate was increased but isoamyl alcohol decreased. The levels of propyl alcohol and isobutyl alcohol fell after short period of time. However, no significance effects of ageing process on methyl acetate , ethyl acetate, isobutyl alcohol, isoamyl alcohol and ethyl lactate(p>0.05) was observed. Where as significance effects of ageing on the propyl alcohol and isoamyl acetate (p<0.05) was observed.

Key words: Grape Fruit, Wine, Fermentation, Ageing .

Introduction

Grape is an important fruit found all over the world, It is used for eating and for production of wine. In China, the total annual production of grapes is about 50,00000 tons per where as production of wine is about 500000 liter.

The exact origin of wine is not cleared. However, used of the grape fruit for production of wine, was “domesticated” before 4,000 B.C. in Mesopotamia and Egypt. Any beverage derived from fermented fruit juice is considered wine. However, wine as we know it is still fermented grape juice from 6,000 years after its domestication (Rapp et al. 1986; Tue, 2001 ).Contrary to common belief that wine making is a relatively simple process as compared to beer fermentation. The sugar-fermenting yeasts are present in the grape skins and naturally begin fermentation whenever there is a break in the grape skin. Where as ethanol is an alcohol made from the fermentation of the carbohydrate or sugar fraction of biomass (plant) materials (Wang et al.2005).

By Improving fermentation methods, the grape juice concentrate could allow fermentation of high alcohol (wines) which eliminate brandy fortification and provide an easier process to produce dessert wines. The strains of yeast (Saccharomyces cerevisiae) are mostly used for fermentations of sugar into alcohols (Buescher et al .2001).

Red wine, as it is commonly produced with red berried grapes. Grape juice - of every grape, including the red berried ones. The wine maker could decide about adding specific yeast cultures in order to have a better control over fermentation as well as giving the wine particular organoleptic qualities. The main and fundamental role of alcoholic fermentation (or primary fermentation) consists in transforming the sugar contained in the must into alcohol and carbon dioxide - a job done by yeasts - however this process has the purpose of developing the secondary aromas of wine as well (Ferreora et al.1995)

The duration of fermentation and maceration depends on the style of wine to be made as well as on the varieties of grapes. In light bodied wines this phase can last three or four days - a sufficient time in order to extract color and some tannins - whereas in full bodied wines this time can also have a duration from one week to one month. The process of alcoholic fermentation will be completed in most of the cases, within one week. Maceration is a the phase in which tannins and gustatory substances are being extracted, is a process that must be scrupulously controlled because excessively long times could result in the extraction of an excessive quantity of polyphenols therefore obtaining very astringent wines with a bitter and mediocre taste. At the end of maceration the wine is separated from the skins and transferred in the aging containers (Park,1991). As opposed to white wines, in red wines malolactic fermentation ( The process in which malic acid is converted into lactic acid and carbon dioxide ) is always done. In red wines malolactic fermentation always plays a positive role because it makes the wine smoother and less astringent. Malic acid accentuates the astringent effect of tannins therefore its transformation into a “sweeter” acid, such as lactic acid, greatly contributes to the roundness of wine ( Bai et al.1994).

The majority of aromatic compounds founded in grape and grape wine have simpler structures. The contents of these organic compounds are organic acids esters, hydroxybenzene and terpene etc (Schreier,1979; Sften et al. 1993)).Furthermore, the odor of wine is due to four esters (ethyl acetate, isoamyl acetate, ethyl hexanoate and octanoate) along with two alcohols, (isobutyl and isoamyl alcohol) and acetaldehyde, all of which are fermentation products ( Ferreira et al. 1995b; Rapp and Mandery, 1986; Perez et al. 2003)

The volatile components of wine are considered as the basic fragrance when supplemented to the wine can improve the quality of wine (Avakyants et al.1981; Falque et al.1995).

Available literature do not support clearly about production of wine form Jufeng grape fruit, a traditional fruit of China.Especially change in aroma compounds of wine during ageing process after fermentation. Therefore, in view of the above facts, the following study was undertaken with following aim and objectives.

(i) To assess Grape fruit (Jufeng) for production of wine

(ii) To study aromatic compounds of fermenated wine

(iii) To determine the ageing of wine after fermentation.

Materials and Methods

Collection of Samples

Samples of grape fruit (Jufeng) were collected from supermarket of Baoding city of Hebei, China. The samples were washed with dist. water to remove unwanted materials. The samples were kept in the plastic bags dully labeled with numbers and locations.

Preparation of Samples

The grape fruit (Jufeng) samples were processed to get juice (stum) with the help of juice machine. In order to prevent the possible oxidative reactions, 50 mg of SO2 and 10g of Ascorbic acids was added immediately after getting juice from juice machine. The reactions mixture was further added 90 g of Sucrose and NH4H2PO4 (300 mg/l) to supply Carbon and Nitrogen. The soluble solid contents were maintained up to21。Bix and pH was adjusted to 3.5.

Activation of Microorganism

In order to incline the culture media, the yeast ( Saccharomyces cerevisiae) was inoculated to the bean sprout juice at 28℃ in incubator. The process was repeated three times to get the growth up to 2×109cell/ml.

Experimental

High-activity of dry yeast (Saccharomyces cerevisiae ) was inoculated with reactions mixture of stum. The yeast numbers up to 5×106cell//ml was achieved during this process, whereas fermentation process was carried out at 28o for overnight. Where as yeast numbers, the soluble solid contents and degree of liquor were measured after every day, in order to determine age of wine, the level of aromatic compound was measured with the help of the gas chromatography (Avakyants et al.1981). The optimized condition like Temperature, Flow rate, N2, H2 and Air pressure was used during the experimental work, when the analysis of aromatic compounds was done with gas chromatography (Augusto and Valente,2000)

Qualitative analysis of Aromatic Compounds

Equal volume (0.1ml) of butyl acetate, ethyl formate, ethyl acetate, ethyl butyrate, propyl alcohol , isobutyl alcohol, isoamyl acetate, isoamyl alcohol, ethyl hexanoate and ethyl lactate was taken in flask and volume was rised to 50 ml with absolute alcohol. The retention time was measured with gas chromatography to determine the peaks of aromatic compounds

Analysis of Wine with Gas Chromatography.

Twenty ml of grape wine was taken in 60 ml spherical flask and 10 ml of dichloromethane was added. The contents of flask were shaken, kept for 10 minutes to separate the organic layers and process was repeated three times. Furthermore volume of sample obtained was concentrated to 1 ml by the KD-concentration vessel. The sample was added with 0.1ml, butyl acetate as internal standard before injection into instruments.

Analysis of Data.

The data obtained from experimental work was analyzed statistically by using Duncan multiple comparison test in the software (SPSS11.0 for Windows ) with minimum significance level 0.05.

Results and discussion

Data obtained after analysis of various parameters are given in Figs1-6

The relationship between growths of yeast with time duration is given in the Fig. 1. It was observed that the growth of yeast increased during first 2 days followed by decrease during third and forth days but stabilized during 5th days of growing period.

The soluble solid contents (13.5% ) obtained in this experiment after first day of fermentation. However, this contents were decreased up to 7.5% in the second day of experiment followed by further decreased up to 6%, during 5th days ( Fig. 2 ). It was observed that yeast (Saccharomyces cerevisiae) fermentation ability became strong when soluble solid contents were 6% at 28 ℃ because time for fermentation process was short and sugar contents were low (Fig .2). Similar results of fermentation were reported by Shen and Feng (1990).

Data given in Fig,3 shows the changes in liquor degree with time period of fermentation during experiment. It was observed that liquor degree was 6.5% in the first day of fermentation followed by increased to 12% during fourth days of experiment. The liquor degree shows trend of escalation, before its stabilization. The results of liquor alcohol obtained in the present study were slightly different than the results reported by Blanch et al. ( 1997)

Fig1. Growth curve of the yeast (Saccharomyces cerevisiae) during different time period.

Fig 2 Relationship between sugar utilization by yeast (Saccharomyces cerevisiae) and time duration.

Fig 3 Degree of liquor during different time duration

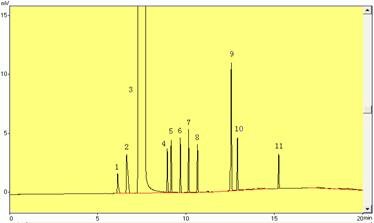

The data about qualitative estimation of aromatic compounds are given in Fig.4.The mixed standard (used in the experiment) was analyzed with gas chromatography for comparison with contents of wine and the order of peaks obtained were. Ethyl formate, ethyl acetate, ethanol , ethyl butyrate, propyl alcohol, butyl acetate , isobutyl alcohol, isoamyl acetate, isoamyl alcohol, ethyl hexanoate, ethyl lactate.

Fig.4 Peaks of main aromatic compounds in mixed standard

The results of aromatic compounds obtained from wine was analyzed by gas chromatography (Fig.5). It was observed that these aromatic compounds were present in wine in the order of lower to higher chain alcohol.

Fig.5 Relationship of Aromatic Compounds of Fermented Wine with Time duration (days)

It was observed in present experiment that in Jufeng stum, the main fragrant ingredient was ethyl formate, ethyl acetate and propyl alcohol. Whereas the main fragrant ingredient of grape wine (jufeng) in fermentation process was the ethyl formate, ethyl acetate, propyl alcohol, isobutyl alcohol, isoamyl acetate and isoamyl alcohol, but butyl acetate, ethyl hexanoate and ethyl lactate was absent. As stum contained lower fragrant ingredients, therefore contribution of grape's fragrance in fermentation process for grape wine was lower (Fig.5).However, similar results were reported by Tamborra (1992) & Cui ( 1995)

The various aromatic compounds of grape wine (jufeng) during fermentation process were found in the trend of escalation. The ethyl formate, propyl alcohol, isobutyl alcohol and isoamyl acetate escalated slowly. While isoamyl alcohol and ethyl acetate showed high escalation. However, higher contents of isoamyl alcohol followed by the ethyl acetate were found during this experiment ( Fig.5).

The statistical analysis of data shows that ethyl formate content (p> 0.05) was not effected by time duration while the ethyl acetate, propyl alcohol and sobutyl alcohol contents (p<0.05) were got significance effects (Fig.5)

Fig.6 Relationship with main aromatic compounds with time (day) in ageing of wine after fermentation process

In the ageing process of wine after fermentation, the main ingredients of grape wine (jufeng) ethyl formate, ethyl acetate, propyl alcohol, isobutyl alcohol, isoamyl acetate, isoamyl alcohol and ethyl lactate were found. The ethyl lactate was main compound produced during ageing process of grape wine by acidic fermentation of malic and lactic acid (Fig.6).

Higher contents of isoamyl alcohol followed by ethyl lactate were also found in present study. Where as contents of the ethyl formate, ethyl acetate, isoamyl acetate and ethyl lactate were increased gradually followed by reduction in the contents of isoamyl alcohol with the function of time. Furthermore the results of ageing process obtained in the present study were found more reliable as compared to results reported by some other authors including Li (2000); Bitteur (1992) & Miranda (1992).

The statistical analysis of data by SPSS shows that during ageing process of the grape wine ethyl formate, ethyl acetate, isobutyl alcohol, isoamyl alcohol and ethyl lactate contents (p> 0.05) was not affected by time duration. Where as significant effects were observed on contents of propyl alcohol and isoamyl acetate l (p<0.05).

Conclusion

It is concluded that wine from grape fruits (jufeng) is an important beverage which always need some improvement during production. The different parameters study in present study will help to produce good quality wine by different industries in People Republic of China. The contents of important aromatic compounds studied during ageing process will help to increase shelf life of wine. It is therefore expected that by using these parameters quality of wine will be improved along with lower cost for consumers.

References

Augusto, F. A and L. P. Valente.2000. Screening of Brazilian fruit aromas using solid-phase microextraction-gas chromatography-mass spectrometry. J. Chromatgr. 873 (1): 117-127.

Avakyants, S. P., E. G. Rastyannikov and B. S. Chernyaga. 1981. Khromato-mass -spektrometricheskoe issledovanie. Letuch. Vesnch. Vina. 41, 50-53.

BaI, C. H., S P. Tian, Y. Ou and Z. C. Cao . 1994.Changes of aromatic alcohols and alkenes in peels of oranges after waxing during storage. Plant Physio. Communicat.30 (4):272-274.

Blanch, G. P., G , Reglero and M.Herraiz .1997.Rapid extraction of wine aroma compounds using a new simulations distillation-solvent extraction device.Food Chemist. 56(4): 439-444

Bitteur, S. B. 1992. Carbonicanaero biosis of muscat grapes. Changes in the profiles of free and bound volatiles. Am. J. Enol.& Viticult. 43(1):41-47.

Cui, G. Y. 1995.Plight and foreground of research on flavor chemistry. Food Scie., 16 (10):24-28

Falque, L. E., Fernandez, E, Darriet and P, Dubourdieu . 1995.Wine aromatic compounds by GC-MS-Sniffing. Aliment. (Espana), 264, 81-84

Ferreira, V., P. Fernandez , C. Pen , A.Escudero and J. F. Cacho. 1995b. Investigation on the role played byfermentation esters in the aroma of young Spanish wines by multivariate analysis. J Sci Food and Agricult. 67, 381-392.

Li, H. M. 2000.Research on technics of sweet red JuFeng grape wine. Appli. Sci. & Technol. 5 , 29-30

Miranda, L. 1992. Identification of additional ordor-active compound in pinot nior wines. J. Agricult & Food Chemist. 1, 90-92

Park, S. K and J.C.Morrison. 1991. Distribution of free and glycosidically bound monoterpenes in the skin and mesocarp of muscat of Alexandria grape during development. J. Agricult & Food Chemist. 39 (3):514-518

Perez, P., J.M. Lopez and E. Gomez. 2003. Differences in major volatile compounds of red wines according to storage length and storage conditions. J Food Composit & Analy. 16,697-705.

Rapp, A and H. Mandery. 1986. Wine aroma. Experientia. 42, 873-884.

Schreier, P. 1979. Flavor composition of wines: A review. Critical Reviews in Food Sci and Nut. 12, 59-111.

Sefton, M.A, L. Francis and P.J. Williams. 1993. The volatile composition of chardonnay juices: A study by flavor precursor analysis. Am. J. Enol.& Viticult. 44(4):359 -369.

Shen, R and S.H Feng Q. 1990.Analysis of the aromatic components of ratafee. Food and Ferment. Indust. 4, 35-43.

Tamborra, P.1992. Influence of maceration on free and glucoside-bound terpenes in Moscatello selvatico wines. Rivistadi viticult. Edinolo. 45(2) 35-45

Wang, J.S., J. Wang and M. Gulfraz.2005. Efficient Cellulase Production from Corn Straw by Trichoderma Reesei LW1 through Solid State Fermentation Process.Ethnobot.Leaf.

Wu, T. X and P G. Hu .1998. Studies on the Actinidia chinensis beer. Food Indust. 4,11-12